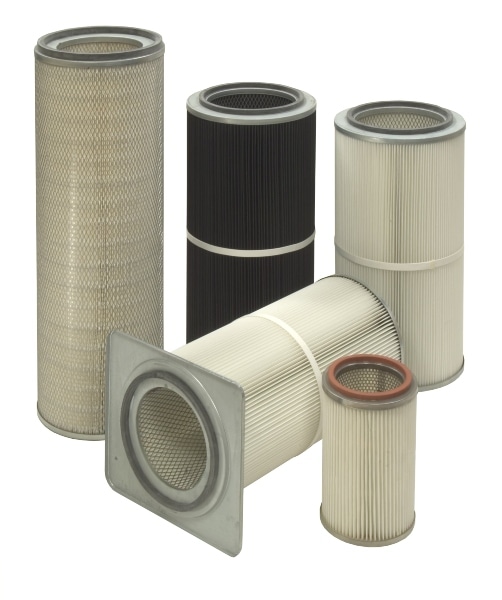

Fab-Tex Filtration manufactures a complete range of cartridge filters for dust collection and air pollution control systems.

Our filters are designed to meet and exceed OEM specifications for construction and operation. They are robust and reliable and able to withstand the incredibly harsh environments to which they are exposed.

Cartridge Air Filter Manufacturers

Fab-Tex has been manufacturing the highest quality filter cartridges for over 25 years, it’s what makes us the filter experts! We are driven to exceed expectations in all aspects of the replacement filter purchasing process.

Industrial Cartridge Filter Selection

Our catalog holds over 6000 unique part numbers to help us quickly cross-reference the dimensions of your existing filter. All of our filters are custom made to specifications. By knowing the right questions to ask, we will ensure you receive a more effective filter than an “off the shelf” replacement product. We strive to make every filter exceed the expectations of a standard filter.

Shop Filter Cartridges

Shop Filter Cartridges

Our filter cartridges are engineered to the highest standards under strict quality control. Fab-Tex has tested and verified our cartridge filter media to ensure they offer the same or better performance as any OEM filter – without the brand name cost. We’ve utilized our years of technical experience to ensure we provide the best quality filter media and components available in the marketplace.

Replacement Filter Cartridges

Skillfully crafted in a wide variety of sizes, replacement cartridge filters are available to fit almost all dust collection equipment available in the marketplace today. Our customers first come to us for superior quality replacement filters at reasonable prices. They stay with us because they learn that we offer so much more than that.

Custom Air Filter Cartridges

Standard filter replacements are optimized by our unique ability to customize all aspects of the filter manufacturing process. Giving you options in filter media, varying pleat counts and heights, as well as outer and inner supports ensures you have the most effective filter for your specific dust containment needs.

We know every dust collection application is unique. Our passion is collaborating with our customers to ensure you receive the most effective filtration solution for your individual dust collection requirements.

Easy Ordering Process

We make the ordering process easy. Let us help you. Send us a quote request or give us a call at 1-888-9FABTEX to order your better-than standard cartridge filters today!

Custom Options Available in Filter Components

Pleated Filter Media Options

We offer a large selection of filter media available in all our filters. Filter media selection depends on the profile of the dust being filtered and the specific conditions of the dust collector and application. There are many aspects of filtration to consider when choosing the appropriate filter media for an application.

From polyester and paper blends to upgraded Nanofiber FR or PTFE-coated media for fine filtration, Fab-Tex can assist you in the correct media selection to optimize your dust collector’s performance.

| Polyester blend |

Cellulose Based |

- Polyester Based Spun Bonded Polyester MERV 10

- Spun Bonded Polyester HO – MERV 10

- Spun Bonded Polyester Aluminized – MERV 10

- Spun Bonded Polyester/PTFE Membrane MERV 16-18

|

- 80/20 Cellulose/Polyester Blend MERV 10

- Nanofiber FR Fire Retardant – MERV 15

- 80/20 FR Cellulose/Polyester Blend Fire Retardant – MERV 10

|

Pleat Counts

Pleat counts are customized to provide the correct air to cloth ratio for each specific application. Low pleat counts keep pleats spacing open for improved product release and increasing pleat counts can provide extra air flow capabilities to collectors with high air volumes.

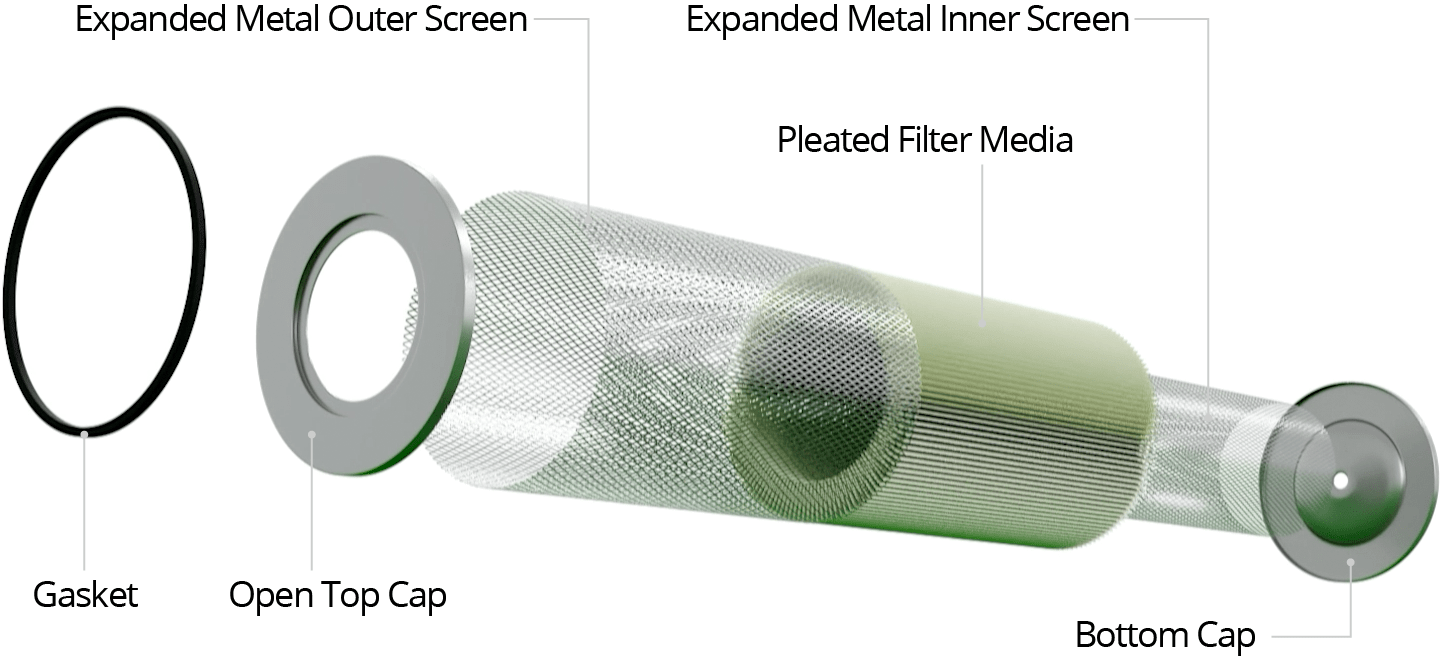

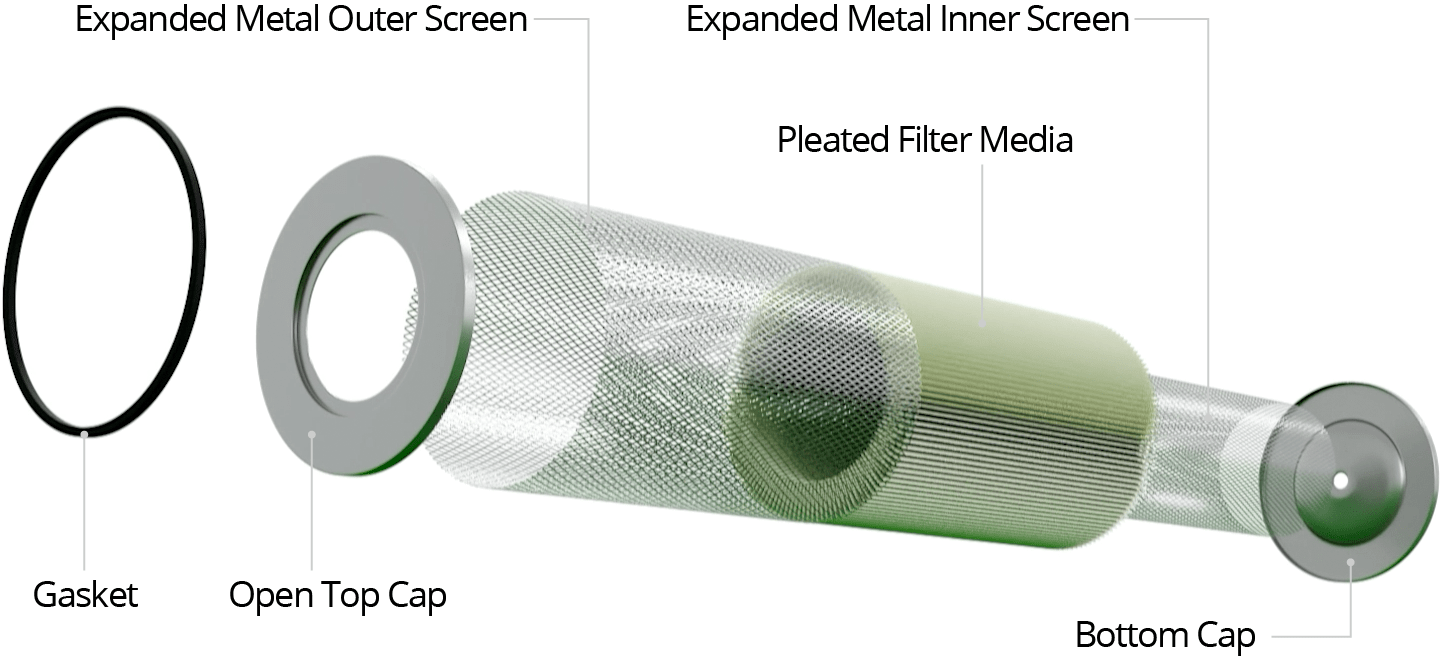

Gasket Options

Gaskets seal the filter to the dust collector to prevent dirty air from escaping back into the work environment. Gaskets can be customized to be placed close to the inside or outside of the cap to match the collector’s exact requirements to provide the tightest fitting seal. Gaskets are available in different widths and heights and materials depending on your requirements.

- .375” W x .5” H | Square

- .5” W x .5” H | Square

- .75” W x .75” H | Square

|

- .5” W x .5” H | Square

- White Silicone FDA

- .5” W x .625” H|D – Shaped

|

- .625” W x .25” | Square

- Isoloss™

- .625” W x .625” H | Square

|

Caps

Top and bottom caps come in thousands of different sizes, shapes and configurations. We offer Farr and Wheelabrator rectangular caps as well as ovals and the standard circular types of all sizes. Cartridge filters can have 2 open caps, or one open cap and the other end having a completely closed end or an end with an appropriately sized bolt hole to configure to your system. Caps can also be made of alternate materials like 304 and 316 stainless steel to protect the filter’s integrity in corrosive applications.

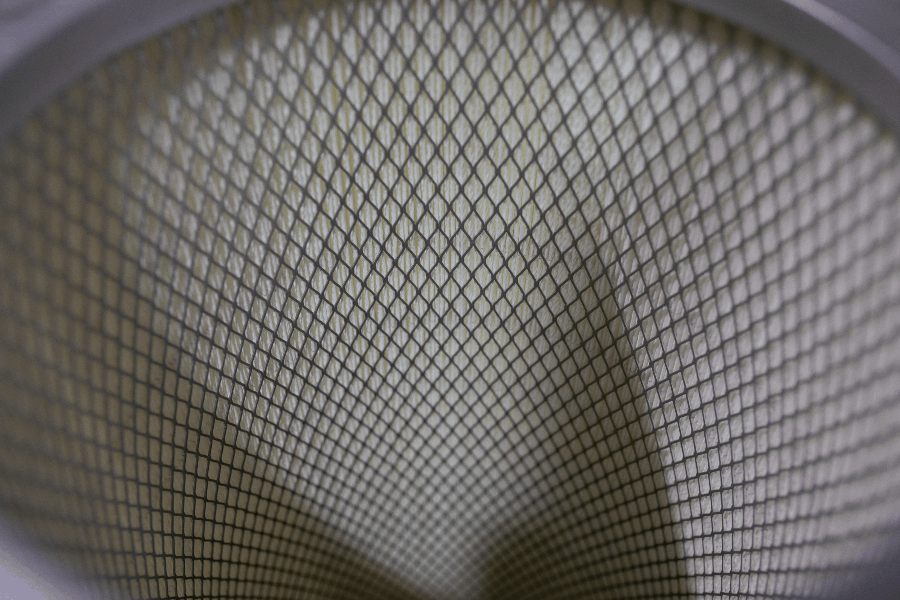

Inner and Outer Screens

Inner and outer metal support screening can be made from expanded metal or perforated metal for extra strength. We can also supply screens in stainless metals for specific corrosive applications.

Bands

Outer bands are used to protect the filter pleats from disturbance during the cleaning cycle. We supply filters with as few as 1 band and up to 5 outer bands depending on the length of the filter. Fab-Tex can also swap out metal exterior screens for 1 or more outer bands for easy cleaning and release in reclaim systems.

Cartridge air filtration uses a cylindrical type filter to remove solid dust particles from the air. These types of filters are designed for high efficiency and easy maintenance, allowing for quick and cost-effective replacement or cleaning. Cartridge filters come in a variety of sizes, types, and materials, and depending on the application, may require surface filtration or depth filtration properties. Cartridge filters are versatile enough to cover numerous industries and applications. Many models have different attachment mechanisms for simple filter replacements without special tools.

| Surface Air Filters and Filtration |

Depth Air Filters and Filtration |

|

Surface filters trap contaminants on the outside of the filter, preventing them from passing through the medium. Over time, particles accumulate on the filter surface, leading to obstructed air flow. If they are not cleaned regularly, they can become plugged prematurely and certainly shorten their life span.

|

Depth filters capture contaminants within the medium, using a thicker or multi-layered structure to trap small particles. Over time, these filters do become plugged and will require cleaning if possible or direct replacement. Again, if they are not cleaned regularly, they can plug prematurely and cause costly down time.

|

HEPA filters are also known as high-efficiency absorbing filters and high-efficiency particulate arrestance filters. Cartridge filters serve to capture larger particles and are typically used as a first-stage filter. Meanwhile HEPA filters serve as a second stage-filter due to their fine filtration capabilities. HEPA filters are designed for high-efficiency air filtration, capturing very fine particles and ensuring high air quality, but tend to plug quickly if used as a first stage filter. HEPA filters are very efficient but costlier to buy and maintain, whereas cartridge filters are initially a lower-cost investment, which will still provide longevity with proper maintenance.

To improve the longevity and efficiency of a system using cartridge air filters, it is imperative to select the correct material for the application involved. To ensure the correct media selection it is very important to advise the manufacturer of the type of dust you are handling and the dust load that you are experiencing at the present time. Depending on the particular use and unique dust characteristics, the manufacturer can advise the best filtering media to supply for your particular application. Filters may need to be replaced more frequently if the dust loads are high and the collector is in use frequently.

Utilizing a magnehelic gauge to track the differential pressure offers immediate feedback on the condition of the filter. For instance, a noticeable rise in pressure differential from the entry to the exit point could indicate that the filter is obstructed, or the media is becoming blinded, a terminology used to describe a filter that is plugged. Using this gauge correctly and consistently can provide you with the information you need to develop a precise maintenance and replacement schedule. This will help protect both the filter, your people and the machinery it safeguards.

If cartridge filters aren’t maintained properly, they can accumulate stubborn, resinous dust layers and prematurely plug. This causes problems for the work environment and unnecessary production downtime. Regular cleaning not only preserves air quality and a good working environment. It also maximizes airflow and prolongs filter life. Adapting a filter maintenance schedule is very important to cut costs and improve the overall system and operation of the plant or process in question.

Don’t be cheap on filter media quality! superior medias withstand wear, manage higher flow rates, and remove contaminants more effectively. To select the best media, conduct a thorough evaluation of your system’s needs, consult experts for advice, and stay up to date on the latest technological advancements in filtration media.

To determine the right filter cartridge for your needs, consider the nature of the dust that accumulates in your workspace and the material it originates from, such as wood, pharmaceuticals, metal, plastic, or organic matter. The right filter media for the environment makes all the difference, particularly if the dust is sticky, abrasive, or chemically reactive. With a properly selected media cartridge filters can work well in many scenarios, including welding, woodworking, manufacturing, and pharmaceutical processes.

The design of the filter media, eg. pleated versus flat, affects particle capture efficiency; choosing the right one will be dictated by the particulate size you need to filter. Micron ratings are a key factor: 1 µm and lower is required for high-purity applications, 5 µm is suitable for general filtration, and 10 µm will be effective in capturing larger particles and safeguarding equipment.

Your system’s air volume and flow rate must align with the filter’s capacity to prevent premature plugging and to maintain quality efficiency, especially for filters with low micron ratings.

Other operational conditions, such as temperature, humidity, and chemical exposure, will influence filter performance and longevity. By taking all these factors into consideration when selecting an air filter, will have your air filtration system working effectively.

- DOE and SOE are distinct types of cartridge end caps. The differences lie in their sealing methods and filtration efficiency.

- DOE cartridges have openings at both ends, facilitating a greater flow rate, allowing more air to pass through per unit of time. They are generally suitable for filtering particles larger than 1 micron. They are easier to install and replace due to their simple sealing mechanism involving gaskets or O-rings and system pressure. However, they may not be as adept at trapping contaminants as SOE cartridges.

SOE cartridges have a single open end and are designed to prevent unfiltered air from bypassing into the output. They are typically equipped with a gasket or O-ring that ensures a tight seal within the filter housing, making them ideal for more refined filtration needs. Although their installation and replacement processes are more involved, the SOE design is considered more secure and reliable, especially in systems that need to prevent unfiltered fluid bypass.

Ultimately, the effectiveness of both configurations depends upon the integrity of the seals. If the seals are compromised, unfiltered substances will bypass the media and filtration is rendered ineffective. When deciding between DOE or SOE cartridges, be sure to consider the specific application, desired level of filtration, operating temperature and pressure, and compatibility with the filter housing.

To ensure the quality of pharmaceutical products, the pharmaceutical industry requires strict air purity levels. Cartridge filters are commonly used as pre-filters in the pharmaceutical industry, where they serve as a safeguard for downstream filters, which are often HEPA filters. By removing larger contaminants, pre-filters prevent clogs or premature fouling of the finer filters that follow. This improves the efficiency and longevity of downstream filters, cutting down the frequency of filter replacements and reducing overall operational costs.

For pharmaceutical operations, Fab-Tex manufactures filters consisting of food-grade epoxies and FDA-approved gasketing materials to ensure compliance with quality standards. Talk to an air filter expert today to learn about the air filters we provide for the pharmaceutical industry.

When choosing a filter cartridge manufacturer, consider your filtration needs, supplier experience, quality control processes, customization options, and customer service. Fab-Tex is a leading OEM filter supplier who offers replacement filters for existing applications and supports new filter designs.

Contact Us

Contact us and once we know your specific requirements, we'll get to work on a solution for you.