Air filters play a critical role in high powered systems filtering contaminants out from air, thereby preventing clogging and unnecessary vehicle damage.

Fab-Tex offers a complete range of high-efficiency air intake filters to protect industrial blowers, air compressors, diesel-or gas-fired Industrial engines and turbines, or any other air intake filtration requirement.

Replacement Air Intake Filters

We are North America’s source for replacement air intake filter elements. Fab-Tex Filtration supplies an ever-expanding line of replacement air filter elements for most OEM equipment. Air blower filters are easy to overlook, but they are critical components for positive displacement blowers. The air filter element protects the blower’s internal components from dirt, dust, debris, and other contaminants that can cause damage. If these contaminants get inside the blower, they can cause scratches or wear down the rotor and housing, reducing lifespan and efficiency.

Additionally, an unfiltered air intake can force the blower to work harder to move the same volume of air. Along with reduced efficiency, poor filtration results in lower peak performance and the potential for failure caused by excessive heat or wear.

Replacement Air Filter Elements for Trust Brands

SMI Solberg, Dollinger, Consler, Endustra, Gardner-Denver, Shawndra Sparks, Sunshine, IFM, or Universal, are some of the many air intake filter replacements built by Fab-Tex to OEM specifications or better. You can trust that Fab-Tex will provide you with an excellent fit filter that will exceed your expectations.

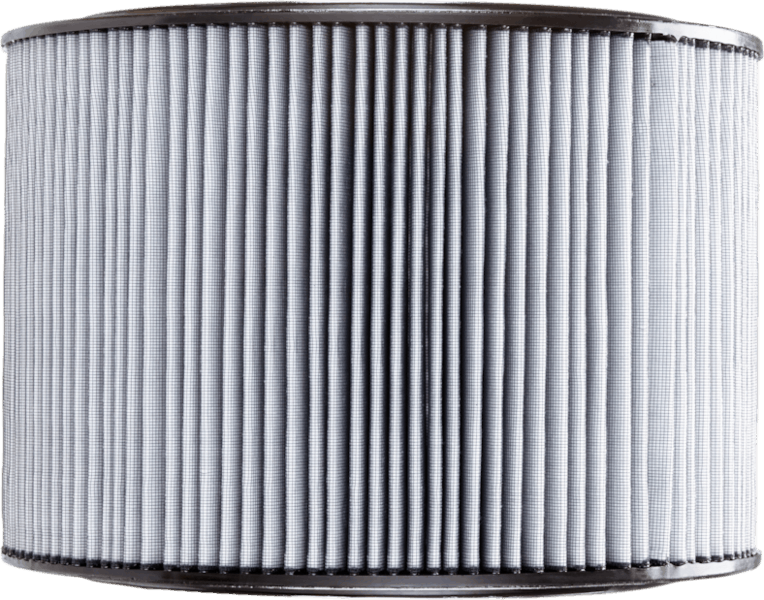

Industrial Air Intake Elements/ Blower Filters

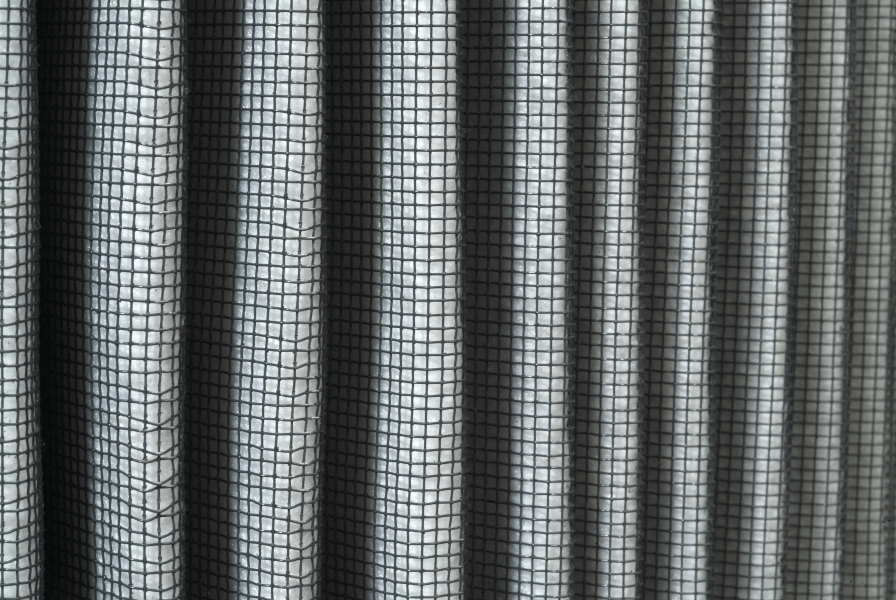

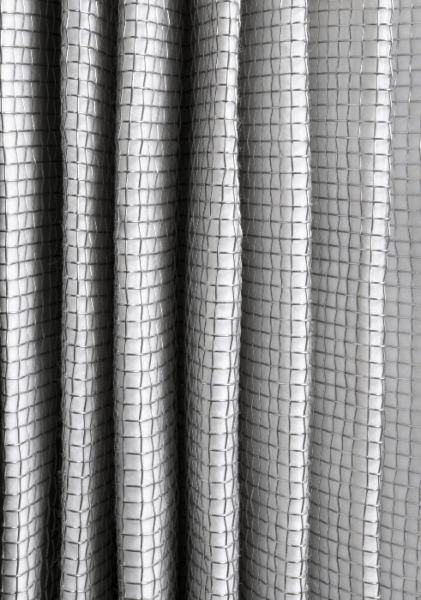

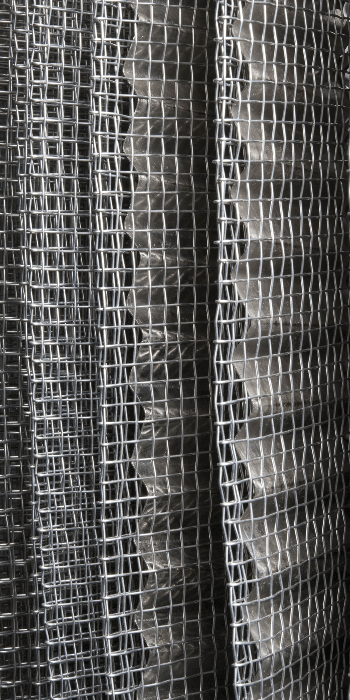

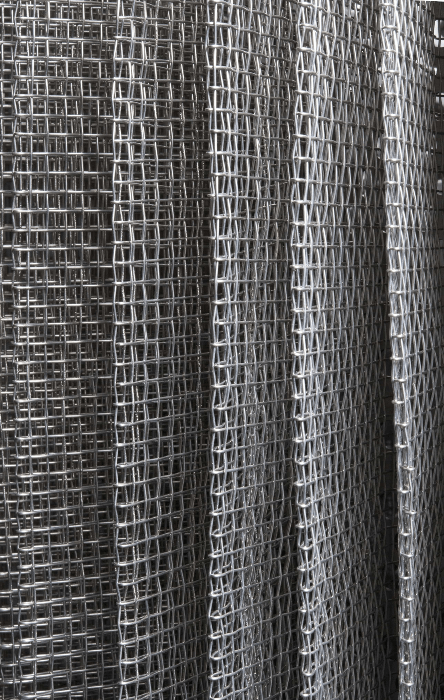

With their heavy-duty construction, combined with rugged 10 micron high efficiency felt medias, our intake  filters are built to withstand the pressure of your high powered vacuum system. Polyester felt media is pleated between 2 layers of epoxy coated wire mesh to prevent pleat collapse under high pressures as well as ensuring a consistent air flow is maintained.

filters are built to withstand the pressure of your high powered vacuum system. Polyester felt media is pleated between 2 layers of epoxy coated wire mesh to prevent pleat collapse under high pressures as well as ensuring a consistent air flow is maintained.

The core and media are then sealed at both ends with a thick urethane compound and built-in sealing lips. Our standard elements are constructed with carbon steel, but we also offer stainless steel options for specific applications where moisture or somewhat corrosive applications may be present.

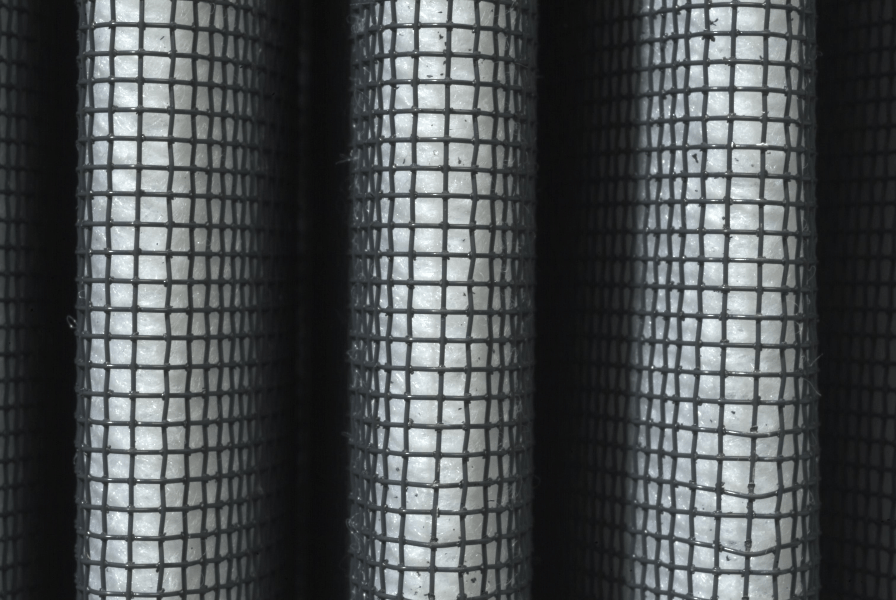

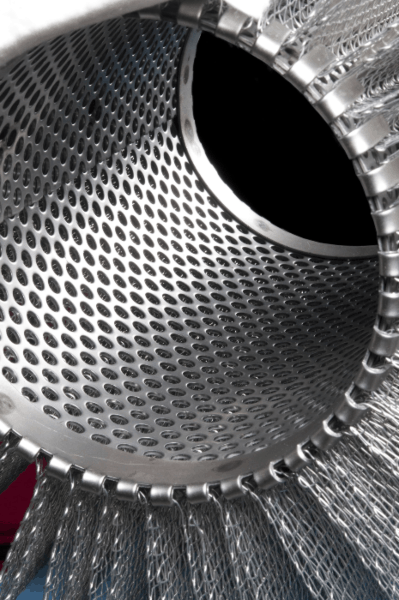

Sewn End Filter Elements

Sewn end elements offer heavy-duty construction utilizing 16 gauge perforated metal inner cores. Filter media is sewn over the pleated wire assembly and thick felt gaskets are attached with adhesive or sewn on both ends. These elements are cleanable and can be factory reconditioned.

Sewn end elements offer heavy-duty construction utilizing 16 gauge perforated metal inner cores. Filter media is sewn over the pleated wire assembly and thick felt gaskets are attached with adhesive or sewn on both ends. These elements are cleanable and can be factory reconditioned.

Options available include Backwash screens, fine spacers and alternate metals and medias depending on your application. Sewn-end filter elements are well-suited for high temperatures or harsh chemical environments where molded-end filters might deteriorate.

How Fab-Tex Air Intake Filters Make A Difference

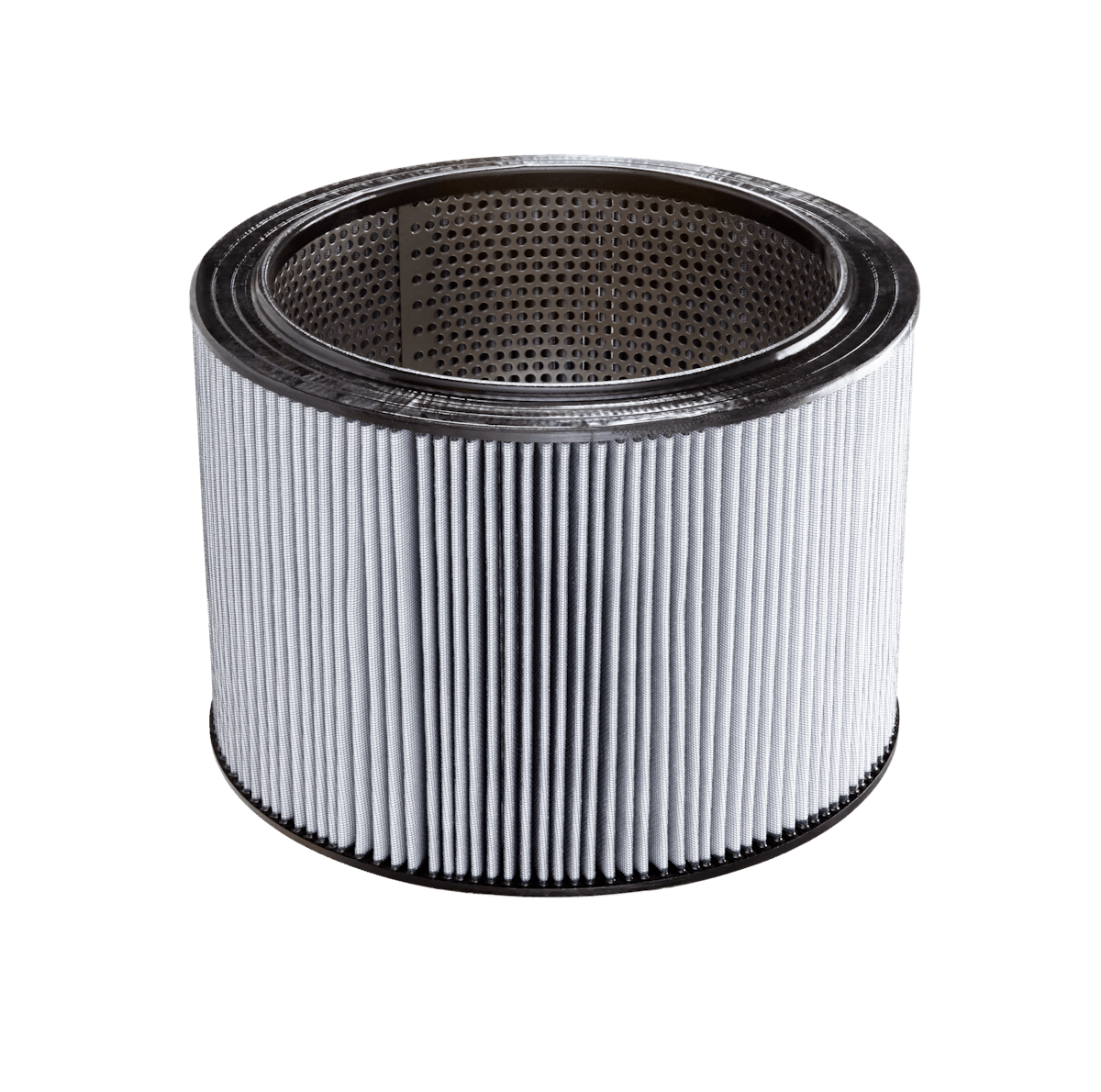

Air intake filters are carefully engineered to meet and exceed all OEM specifications. All 10 micron felt elements provide excellent permeability from 120-150 CFM per ½” w.g. They provide maximum air flow, while still offering high-efficiency dust retention from 0.3 microns to 200 Microns depending on media choice. They can handle air volumes from 100 to 6,000+ CFM.

Air intake filters are constructed in hundreds of size configurations. With molded urethane ends for sealing and our standard 10-micron Polyester felt, you can count on these rugged filters to handle your toughest jobs. Air intake filter elements are also available in paper and other micron rated polyester felts for unique applications.

Custom Air Intake Filter Solutions

Fab-Tex also provides unusual and custom size filters for non-standard applications. All of our filter elements are specifically designed to remove atmospheric dust from the air intake for engines, fan & blower inlets, compressors and turbines.