Air filters help improve air quality, according to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), by trapping and collecting particles.

Air filters help improve air quality, according to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), by trapping and collecting particles.

ASHRAE 52.2 Standard

The generally accepted North American method of determining filter efficiency is testing filters to the ASHRAE 52.2 standard. The test returns a MERV rating (Minimum Efficiency Reporting Value) for the tested filter. The MERV measures how effectively the filter removes particles from the air.

Filter efficiency is tested by running 6 measured dust loads with particulates in size range of .3 to 10 microns through the filtering media to establish the media’s ability to capture different particle sizes. The higher the MERV rating, the more influential the filter is at trapping sub-micron particulates.

*It should be noted that the ASHRAE 52.2 test procedure returns the MINIMUM efficiency value for the tested filter. In actual use, once the filters have been coated with particulate, the filter efficiency would be much higher than that reported through the test.

MERV Filter Ratings & Efficiency

When choosing the right filter, airflow restriction is an important consideration. Higher MERV-rated filters tend to restrict airflow because they have smaller pores to capture smaller particles. If such filters are used with a system not designed to handle the higher resistance, it creates strain, lowering the system’s overall efficiency. As a result, higher MERV ratings do not always equal a ‘better’ filter for an application.

Looking for the Air Right Filter?

Speak to a Fab-Tex Filter Expert Today

MERV Rating Chart

A MERV rating chart helps when comparing filters made by different manufacturers. In addition, MERV filter ratings are the standard for measuring and reporting how efficient air filters are in the air filtration industry.

Use the following MERV rating chart to determine the best filter for your application. Fab-Tex supplies air filters for industrial dust collectors and air pollution control uses.

Efficiency Reporting Value (MERV) |

|||

|---|---|---|---|

19 - ULPA 18 - HEPA 17- HEPA |

Pharmaceutical Manufacturing Radioactive materials Clean rooms/ Lab Settings |

< 0.30 pm particle size (Small), Viruses, carbon dust, combustion smoke | 99.7% or better on less than 0.30-micron particle size ● HEPA Filter Media ● Final Stage Filters ● Bag & Box Filters |

15 14 13 |

Superior Commercial Buildings Welding fumes Surgery/Hospital Inpatient Care Smoking Lounges |

.3 -1.0 pm Particle Size (Small) All Bacteria, smoke, sneezes, plasma and laser cutting, food manufacturing, welding fumes |

95% or better on 0.3–1.0 micron particle size ● Nanofiber Media Cartridges ● PTFE Coated Media Filters ● Cartridge Filters |

11 10 9 |

Manufacturing Facilities Better Commercial Buildings General Nuisance Dust Food Processing |

1.0-3.0 pm Particle Size (Medium) Coal dust, lead dust, wood dust, fibrous dust, legionella, humidifier dust, milled flour, auto emissions |

85% or better on 1.0–3.0 micron particle size ● Spun Bond Polyester Media ● 80/20 Cell/Poly Blend Media ● Cartridge Filters ● Bag Filters |

7 6 5 |

Good Commercial Buildings General Nuisance Dust Industrial Workplace Paint Booth Inlet |

3.0-10.0 pm Particle Size (Large) Dust mites, pollen, sanding dust, spray paint dust, textile fibers, carpet fibers, dusting aids, and cement dust |

Less than 80% on 3–10 micron particle size ● Cellulose Media ● Pleated Filters ● Cartridge Filters ● Throwaway Filters |

3 2 1 |

Minimal Filtration Residential Furnace Window/AC Units |

>10.0 pm Particle Size (Large) Dust mites, pollen, sanding dust, spray paint dust, textile fibers, carpet fibers |

Less than 20% on 3-10 micron particle size ● Throwaway Filters ● Washable Filters ● Electrostatic Filters |

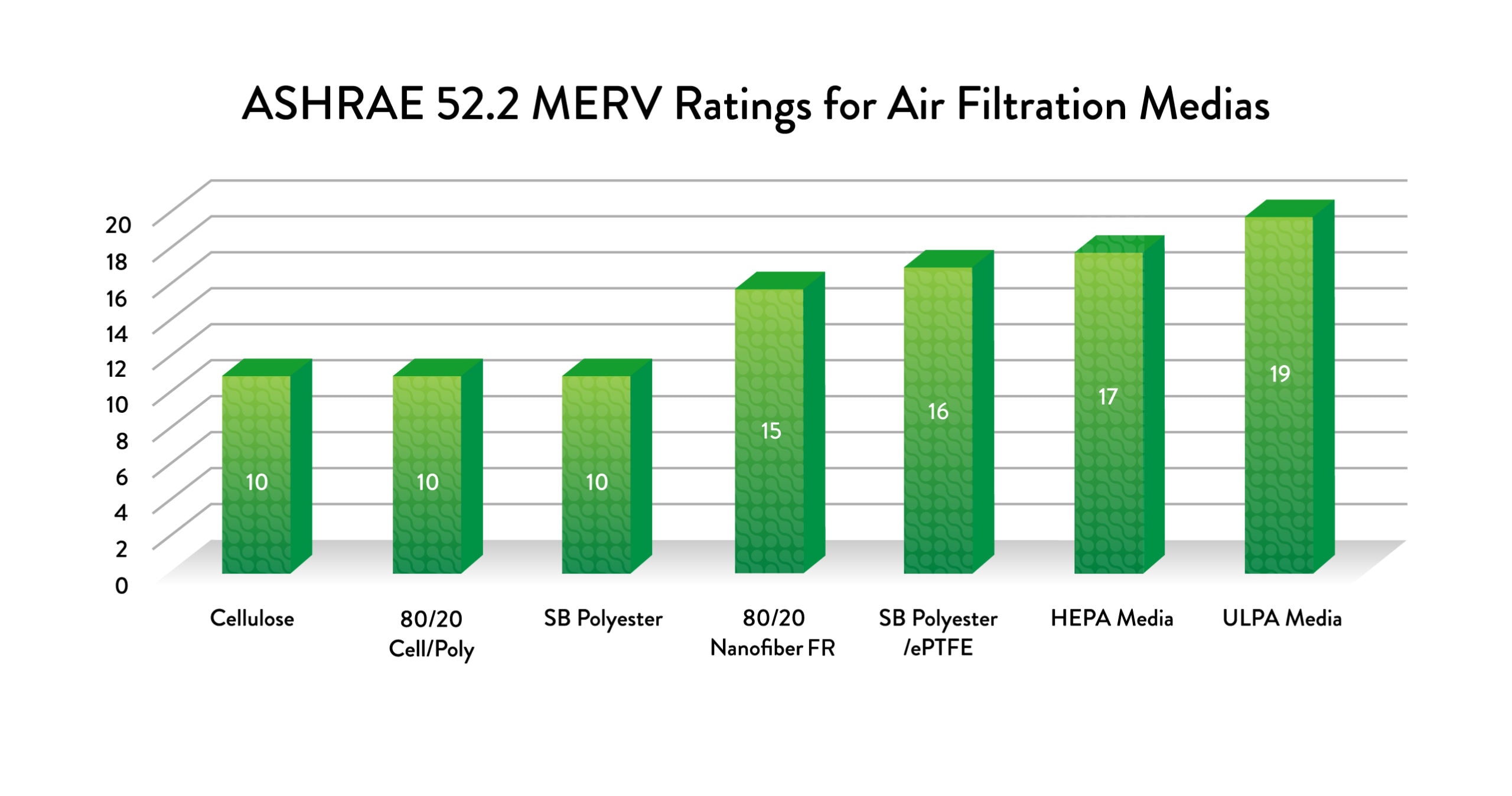

MERV Ratings for Air Filtration Medias

MERV Ratings for commonly used filter medias are as follows:

- 100% Cellulose Media – MERV 10: 50% – 65% efficiency on particulate in the 1-3 micron range.

- Spunbonded Polyester – MERV 10: Greater than 80% efficiency on particulate in the 1-3 micron range.

- 80/20 Cellulose/Polyester – MERV 11: 65% – 80% efficiency on particulate in the 1-3 micron range.

- 80/20 Cellulose/Polyester with Nanofiber Membrane – MERV 15: Greater than 90% efficiency on particulate in the 1-3 micron range and 85% – 95% efficiency in the .3 – 1 micron range.

- Spunbonded Polyester with PTFE Membrane – MERV 16: Greater than 95% efficiency on particulate in the 1-3 micron range and greater than 95% in the .3 – 1 micron range.

- HEPA Medias – MERV 17: 99.97% efficiency on .3 micron particulate.

- ULPA Medias – MERV 19: 99.99999% efficiency on .3 micron particulate.

Selecting the Proper Industrial Air Filter

Advancements in filter media, materials, overall design and construction (including Fab-Tex’s Tandem Pleat Technology for high-efficiency filters) have resulted in an explosion of high-performance filters. Fab-Tex works with customers across various industrial environments that rely on industrial air filters, including:

● Critical food applications

● Welding shops

● Manufacturing environments

● Powder Coating facilities

● Pharmaceutical applications

● Woodworking industries

● Environmental Service Providers

And anywhere else, dust containment equipment is present!

Filters manufactured by Fab-Tex filters offer the best in efficiency, performance and expected life cycle.